Explore Our Product Range

At Technotrend Innovations, we specialize in providing advanced solutions for industrial air treatment. Our comprehensive product range includes high-performance Refrigerated Air Dryers, compressed Air Dryers,Air Compressors, Compressed Air Filters, and Auto Drain Valves, all designed to enhance the efficiency and reliability of your compressed air systems. Whether you're looking to maintain optimal air quality or ensure the longevity of your equipment, our products are engineered to meet the highest standards of performance and durability.

Browse Products

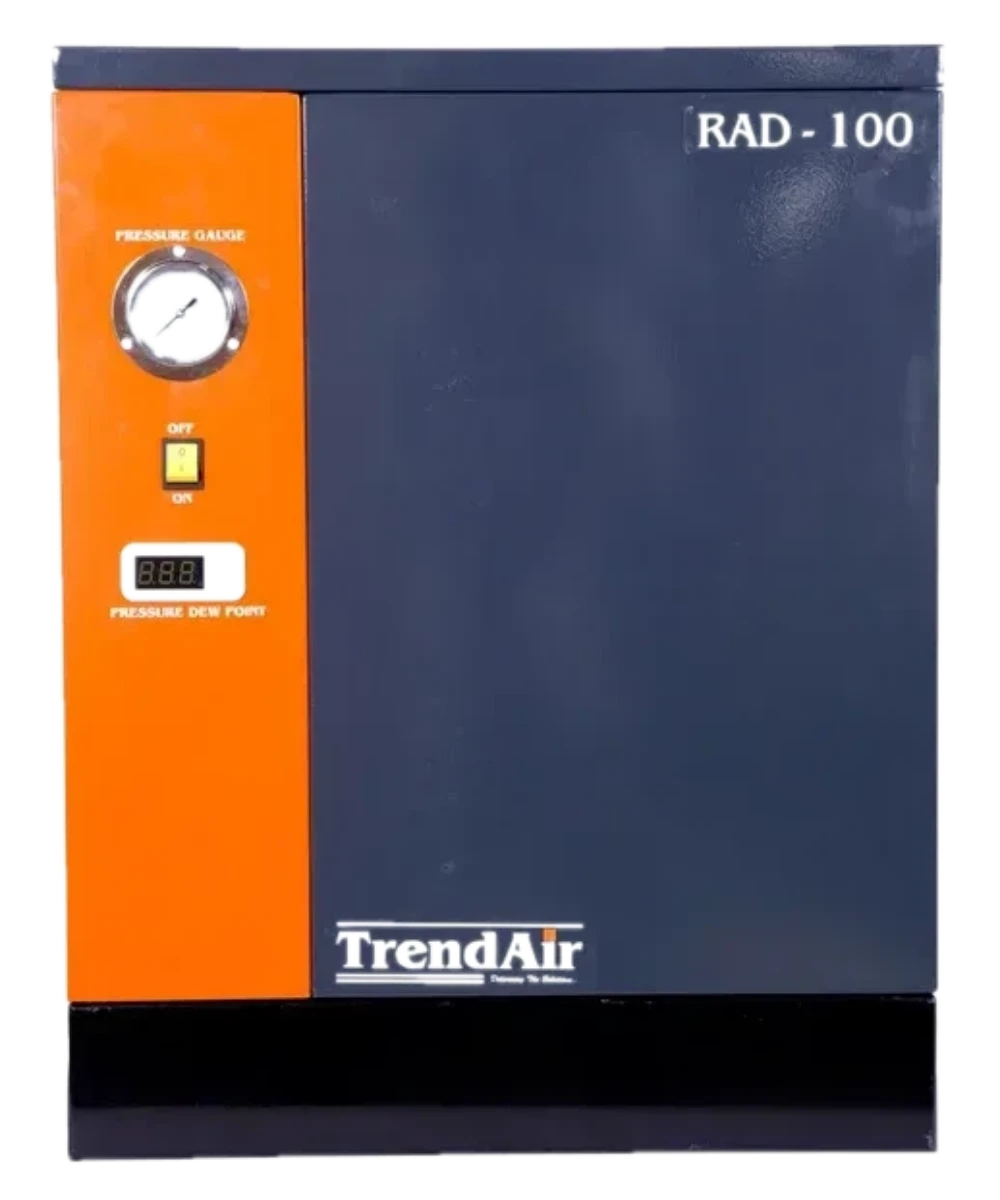

Our product range for Refrigerated Air Dryer

- Stable dew point (~3 °C) under varying load conditions to ensure consistent dryness of compressed air.

- Automatic condensate drainage via timer or electronic drain to remove moisture without manual intervention.

- Efficient heat exchange & low pressure drop using copper-tube / aluminium-fin condenser design and optimized fin spacing.

- Robust construction & corrosion resistance — powder coated housing, well-sealed cabinet, designed for industrial / humid environments.

- Machine shops / CNC / VMC / tooling operations — to supply dry air to pneumatic equipment, prevent corrosion, tool damage.

- Paint booths / powder coating / finishing lines — to avoid moisture interference, defects, blistering.

- Pharmaceutical / medical / laboratory systems — offering dry, clean compressed air for sensitive processes.

- Food & packaging / bottling / beverage plants — where moisture in compressed air could cause contamination, corrosion, or product spoilage.

| Specification | Value |

|---|---|

| Air flow / Capacity | 100 CFM |

| Power consumption | 5 kW |

| Parameter Value / Notes Air flow / Capacity 100 CFM technotrendinnovations.in Power consumption 5 | ~15 bar |

| Dew point temperature | ~ 3 °C (± variation) |

| Refrigerant | R-134a |

| Maximum ambient temperature | ~ 45 °C |

- Production capacity & delivery time:: The “Compressed Air Dryer” listing says production capacity 20 units per day and typical delivery ti

- Quality & testing procedures:: They mention hydrostatic testing of the air side, purging and leak testing of the refrigeration loop

- Constant dew point (~3 °C) under variable load, ensuring dry compressed air irrespective of demand.

- Automatic condensate removal via a timer-based or automatic drain valve (no manual draining required)

- Low pressure drop and efficient heat exchange, thanks to optimally spaced fins and copper-tube heat exchangers

- Rugged, corrosion-resistant enclosure (powder-coated), easy installation and maintenance design

- Machine tool / CNC / VMC workshops where dry air is essential to prevent corrosion / damage to pneumatic systems.

- Paint booths / powder coating lines, to avoid moisture-induced defects in finishes.

- Pharmaceutical / medical / laboratory equipment requiring dry, clean air supply.

- Food & packaging / bottling lines, where moisture in compressed air can cause damage or contamination.

| Specification | Value |

|---|---|

| Air Flow Capacity | 40 CFM |

| Operating Pressure / Pressure Rating | min: ~ 8 bar; Max: ~ 15 kg/cm² |

| Power Supply / Voltage | Single-Phase 230V / 50 Hz |

| Dew Point Temperature | ~ 3 °C (± variation) |

| Maximum Ambient Temperature | 34 degree |

| Refrigerant | R-134a |

| Condenser / Fan / Compressor | Copper tube + aluminium fins + Emerson (or equivalent) |

- Quality testing / standards: Each unit is hydrostatically tested on the air side before delivery; the refrigeration loop is clean

- Delivery & production capacity: The company cites a production capacity of about 20 units per day for this class of dryers; typical

- Automatic condensate removal via timer-based auto drain valve to remove moisture without manual intervention.

- Designed for tropical/humid conditions, with rugged casing (powder coated), good insulation, and materials that resist corrosion.

- Constant pressure dew point at ~3 °C even under varying load conditions, ensuring consistent performance.

- Low pressure drop & efficient heat exchange, thanks to finned copper-tube condenser & well spaced fins

- Compact build, easy installation & maintenance — suitable for small compressor units; includes essential gauges & indicators.

- For small machine shops (e.g. CNC, VMC) where compressed air needs to be clean, dry for tool life.

- Paint booths or powder coating processes to avoid moisture and oil causing defects in finish.

- In hospital / medical gas systems or laboratories to ensure air quality standards are met.

- Packaging / food & beverage lines where moisture in compressed air could contaminate products or packaging.

| Specification | Value |

|---|---|

| Air Flow Rate | 20 CFM |

| Operating Pressure / Pressure Rating | Up to ~15 Bar (test pressure ~10 Bar) |

| Power Supply / Voltage | Single-Phase 230V / 50 Hz |

| Dew Point Temperature | ~ 3 °C (± variation) |

| Inlet / Outlet Connection | 1-inch Threaded Connection |

| Model Weight | ~ 45 kg |

| Condenser Type / Material | Copper Tube & Aluminum Fin; Axial Fan cooled |

- Inlet/Outlet connection: It comes with a 1-inch threaded inlet/outlet connection.

- Refrigerant used: R-134a

- ISO standards: Designed to meet ISO standards for air quality (e.g. ISO8573.1 / ISO7183) for moisture & particulate

- Packaging and shipment:: weight ~45 kg, packed suitably; delivery time generally ~1 week.

- Make: India

- 10 CFM Capacity – Suitable for low-flow compressed air systems.

- Efficient Moisture Removal – Ensures dry air for optimal equipment performance.

- Compact Design – Space-saving and easy to install in industrial setups.

- Reliable Operation – Semi-automatic control for consistent performance.

- Durable Construction – Built for long-lasting industrial use.

- Packaging Industry – Ensures moisture-free air for accurate and reliable packaging.

- Pneumatic Tools – Provides dry air for smooth operation and longer tool life.

- Automotive Workshops – Maintains performance of air-driven equipment and spray painting systems.

- Laboratories & Small-Scale Industries – Supports processes requiring clean, dry compressed air.

- Electronics Manufacturing – Prevents moisture-related damage in sensitive production environments.

| Specification | Value |

|---|---|

| Capacity | 10 CFM |

| Voltage | 230 V |

| Dryer Type | Refrigeration Dryer |

| Automation Grade | Automatic |

| Maximum Ambient Temperature | 45 Degree Celsius |

| Phase | Single Phase |

| Operating Pressure Range | 10 bar |

| Power Consumption | 2.7 kW |

| Inlet/Outlet Connection Size | 1 inch |

| Condenser | Copper Tube and Aluminum Fin |

- Shipping Weight: 45 Kg

- Country of Origin: India

- Compressor Brand: Emerson Make

- Refrigerant: R134a